The Italian Constitution in Article 41 states:

“Private economic initiative is free. It cannot be carried out in conflict with social utility or in a way that could damage security, freedom and human dignity “.

3F has always worked based on the highest principles of Social Responsibility, aware of the ethical role of the company.

Caring for human resources

One of 3F’s greatest assets is its people, talented professionals who strive every day to carry on and grow the company objectives with seriousness and rigour. The enhancement of our collaborators, making it emerge every quality, respect for their needs and the protection of their health and safety are the priority and the basis of the 3F way of doing business.

Sustainability

As a company operating in the industrial sector, we feel we have a great responsibility towards the environment that we are committed to protecting to leave a better world for future generations.

Therefore, in addition to operating in compliance with the laws, in accordance with national and international agreements and standards, national regulations and policies, we have based our action on principles of sustainability, circularity and with an increasing attention to investment in renewable and low-impact sources.

Animated by this spirit, 3F, first in Italy, in the early nineties decided to move from the linear model to a circular one to achieve greater sustainability.

In 1994, the company decided to invest in plants with a lower environmental impact by replacing solvent-based paints with recyclable water-based paints. This choice, not only contributed to lowering the impact on the work environment but have also made it possible to create a facility for the recovery of paint residues from the spray booths. In the latter, through ultrafiltration technology, paint residues can be recycled to create new paint, instead of being disposed of as hazardous waste. In such a way, both the emissions of solvents into the atmosphere and the waste produced are reduced.

Furthermore, among the countless investments of the company aimed at reducing the environmental impact, 3F has been operating for years with two afterburners to treat 100% of the air coming from the paint drying ovens through a thermal oxidation process at over 700 °. C thus eliminating any trace of volatile organic components.

Since 2006 3F has been operating in compliance with its Environmental Management System according to the ISO 14001 standard.

Lastly, temporally, but not least, in the context of the sustainability model that we want to pursue in 2021, it completes the installation of a photovoltaic park on both production sites as a concrete aid to the environment by eliminating the relative emissions of carbon dioxide and other harmful substances typical of the production of electricity from fossil sources.

The estimated reduction of CO2 emissions is over 320 tons/year (estimated figure compared to the average CO2 emissions of the National Thermoelectric Park in March 2020).

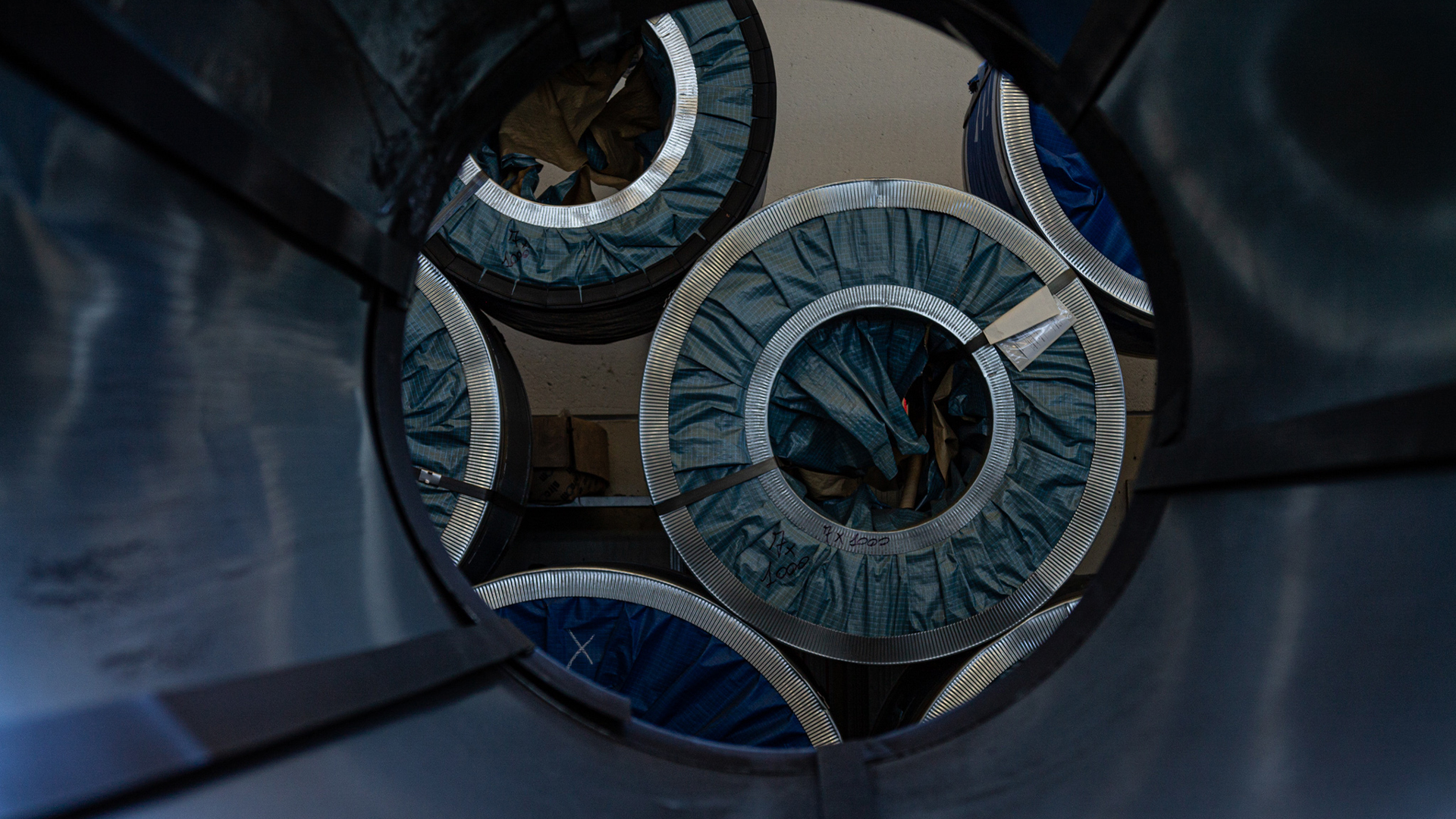

At a product level, 3F is able to offer its customers the best sustainability standards, oriented to the 3 Rs of the Circular Economy (Reduce – Reuse – Recycle):

- REDUCE: the range of 3F steel and plastic products allows the customer to choose the packaging with the lowest weight available on the market for each specific use

- REUSE: all 3F products are suitable for collection and preparation for reuse by specialised companies in the sector (Regenerators). In Italy, most of these companies are represented by the FIRI Association (https://www.associazionefiri.it)

-

RECYCLES: all 3F products are easily recyclable because they are made with a single raw material (Steel or High Density Polyethylene). In Italy, the consortia of the CONAI System (www.conai.org) guarantee the maximum recycling rates for individual products. 3F for its products is associated with the consortia:

RICREA (www.consorzioricrea.org) for the recycling of steel

COREPLA (www.corepla.it) for the recycling of plastic

RILEGNO (www.rilegno.it) for the recycling of wood

But we don’t stop there. We believe the protection of our planet begins with a conscious education. Therefore, we are committed to meeting young people in schools. To show them how large-scale production can provide for the recycling of materials making its transformation processes environmentally friendly.